Offering the right variety of products has been an ongoing challenge for most, if not all, businesses. In many instances, operations, manufacturing, and supply chain leaders (referred to as Operations) view the subject through one lens, while their peers in sales, marketing, and at times, product management (referred to as Sales) view the subject through a different, often opposite lens.

The positions taken by Sales frequently include:

- We need more products to meet our revenue targets.

- The competition is offering a different solution, so we also need to offer a different solution.

- We need products with lower pricing as well as our current offering.

- If we had a wider variety of products, we could dominate the market.

- We need to develop and release new products.

While the Operations' position is often communicated as:

- We need to focus on selling what we have.

- We cannot reduce our inventory and improve our cash position if we continue to add SKUs, without reducing our existing SKU count.

- Our current revenue plan was built using current products, not future products.

- Sales needs to have some level of accountability for our excess and obsolescence inventory provisioning expenses.

Both positions have merit, and a natural tension does exist between Operations and Sales when it comes to SKU count. A company must balance these two viewpoints and find a middle path that delivers the required results to the business, its customers, and its employees. But deciding what the appropriate number of SKUs is for your organization is challenging, and many companies fail to make the right decision. Niche markets have developed as the result of the "supply chain slop" that is the direct outcome of having too many SKU offerings and a misalignment between sales forecast, supply management, manufacturing, and executive management. TJ Maxx, Overstock.com, and Liquidation.com are just a few examples of resellers of excess products. In addition, nearly countless component resellers exist that buy one company's excess and/or obsolete inventory at a discounted rate and sell it to other companies at a profit. In the process of doing so, these companies address supply shortcomings for both the sellers and buyers of these components.

In spite of the difficulty associated with it, SKU rationalization is a worthwhile goal. When the desired balance is achieved, financial performance and workplace culture improve. We believe the best way to approach SKU rationalization is one that relies on quantifiable performance metrics and building better alignment between Operations and Sales.

Complex tradeoffs

When companies begin the process of SKU rationalization, it is crucial that they understand the impact that having too many or too few SKUs can have on both Operations and Sales (and ultimately financial) performance. The following are some of the primary impacts that adding SKUs can have on a company's operations:

- More data to collect and analyze,

- Additional storage space required,

- Additional suppliers to manage,

- Greater employee angst due to having to balance shifting priorities between different SKUs and the need to respond to increased product-availability and supply chain emergencies,

- Additional labor cost due to managing increased product variety and additional transportation expense due to expediting materials,

- Increased complexity of managing more custom components with different life cycles,

- Decreased forecast accuracy, order fill rates, and customer satisfaction,

- Increased excess and obsolescence inventory provisioning, product reconfiguration, logistics, and engineering change-management expenses, and

- Decreased operating margins.

And yet, companies need to be careful not to go too far with their SKU rationalization efforts, as too few SKUs can have a negative impact on sales (and ultimately on financial performance). Listed below are some of the primary favorable impacts that adding SKUs can have on a company's sales:

- More customers,

- More revenue,

- Wider market capture,

- Deeper market penetrations,

- Increased competitive positioning,

- Tighter customer engagement and higher level of customer relevancy,

- Increased revenue associated with add-on products, and

- Increased service revenue.

Numerous studies, books, and seminars have focused on how to manage the tradeoffs between Operations and Sales.1, 2, 3, 4 Models and systems have been developed to help companies optimize the number of SKUs. Some feel very strongly that companies need to offer more products and extend product life cycles in order to meet revenue goals, customer requirements, and personal compensation goals. Others believe that constraining and/or reducing SKU offerings will decrease operating costs by improving efficiency, and thereby free up cash and improve financial performance. So, while valuable learnings and benefits have been derived from these studies, there is no clear consensus established, and SKU rationalization arguments continue across many markets to various degrees.

Complicating matters is the fact that the relationship between SKU count and a company's performance is nonlinear in nature. Typically, if a company reduces its SKU count, the company will see a decrease in the negative impacts on operational performance described above. However, the same is not necessarily true for the sales impacts noted above. Some studies have found that sales aren't necessarily negatively impacted as SKUs are reduced. Consider, for example, an extensive study of a soft drink bottler with 108 distribution centers that evaluated how product-variety decisions affected the company's unit fill rate and sale performance.5 The study revealed that fill rates were negatively associated with increasing product variety but at a diminishing rate. In other words, the more products that a company offered, the lower its fill rate, but the impact on fill rate decreased themore SKUs were added. The study also showed that the impact of increased product variety on sales is initially positive but also at a diminishing rate—meaning that while an initial increase in product variety tended to lift sales, that lift became less the more products were introduced. Furthermore, increasing product variety beyond a certain level actually resulted in lower sales as product cannibalization eliminated the positive effects from variety-seeking customer behaviors. In short, too many product offerings can negatively impact both operational and sales performance.

The study suggests that if a company ignores the negative effect of too much product variety on sales, it can overestimate the associated benefits of product variety. This is intriguing in that by understanding the negative effect of too many SKUs on sales performance, companies can better align Operations and Sales perspectives on SKU rationalization.

Conquering complexity

In general, businesses face the following primary challenge with regards to SKU rationalization: They need to take full advantage of the growth that can be gained by exploiting the SKU complexity that customers value while also shedding nonvalue-adding SKUs (that is, "value destroyers"). But how can a company determine when that complexity is leading to added sales and profit and when that complexity does not add value (or not enough value to offset the added complexity involved)?

In their 2004 book Conquering Complexity in Your Business, Michael George and Stephen Wilson outline some helpful quantitative methods for identifying how much nonvalue-adding complexity exists in your enterprise and where it lies.6 We believe these methods can be used to help identify which SKUs can be added or eliminated from your product portfolio.

One way that George and Wilson quantify complexity is by looking at process cycle efficiency (PCE), a metric that gauges how well a process works. This metric applies directly to SKU count in that higher SKU counts create a higher level of complexity in a variety of processes including product design and release, managing the supply chain, manufacturing, service, and product end-of-life,as well as all the required supporting administrative processes. PCE provides a ratio showing value-add time (or the amount of time in the process during which value is added) compared to (or as a percentage of) the total process (or lead) time. The basic equation for PCE is defined as:

Process cycle efficiency = Value-add time / Total lead time

George and Wilson expand on the above to break down value-add time and total lead time in the following way:

PCE = 2V (1-X-PD) / N(2A+1) S

Where:

- V = Total value-add time in process

- X = % of products or services with quality defects

- P = Processing time/unit

- D = Total demand for the products or services

- N = The number of different offerings

- A = The number of activities or steps in the process

- S = Setup time

Thus, they conclude that as increases occur in product variety (N), the number of activities in the process (A), and setup time (S), process cycle efficiency decreases. Higher SKU counts deliver lower PCE or value-add time, which in turn negatively impacts financial performance.

SKU rationalization is a critical driver of improving PCE as SKU proliferation increases nonvalue-added time and costs (including up-front product development and release costs, sales and marketing expenses, inventory investment, service/support costs, and excess and obsolescence inventory provisioning costs).

When applying this formula, we see that, in general, low-volume products experience a higher variation in demand. As the number of low-volume product offerings and variation in demand for these products increase, PCE decreases. Consider the manufacturing environment where low runners are built less frequently and held in inventory, which leads to increased warehousing expense and potential increases in obsolescence. This combination of product count and demand variation has a negative impact on the ability to successfully manage (defined as cross-functional alignment and enhancedfinancial performance) business performance improvement. Because of this, low-volume SKUs should initially be considered for SKU rationalization. All other variables remaining the same, lower demand (D) for a product will deliver a lower PCE.

Experience shows, however, that trying to eliminate these low-volume SKUs may be met with resistance from Sales, even if they are shown to be negative drivers of PCE. Sales may argue that there may be customers of these SKUs that are "going to procure our next-gen products when they enter their next buying cycle, but only if we continue to sell and service these current products." Thus, we may be unwilling to eliminate these low-volume SKUs, not so much because of the impact on our current revenue stream but because of the potential future gains, which may never occur.

In support of addressing the above Operations and Sales perspectives, in conjunction with PCE, SKU-related complexity can be viewed strategically by using an indicator known as economic profit (EP), which is the real profit after considering all of the resources the company has consumed. Improving the profitability of product offerings through SKU rationalization favorably impacts EP.

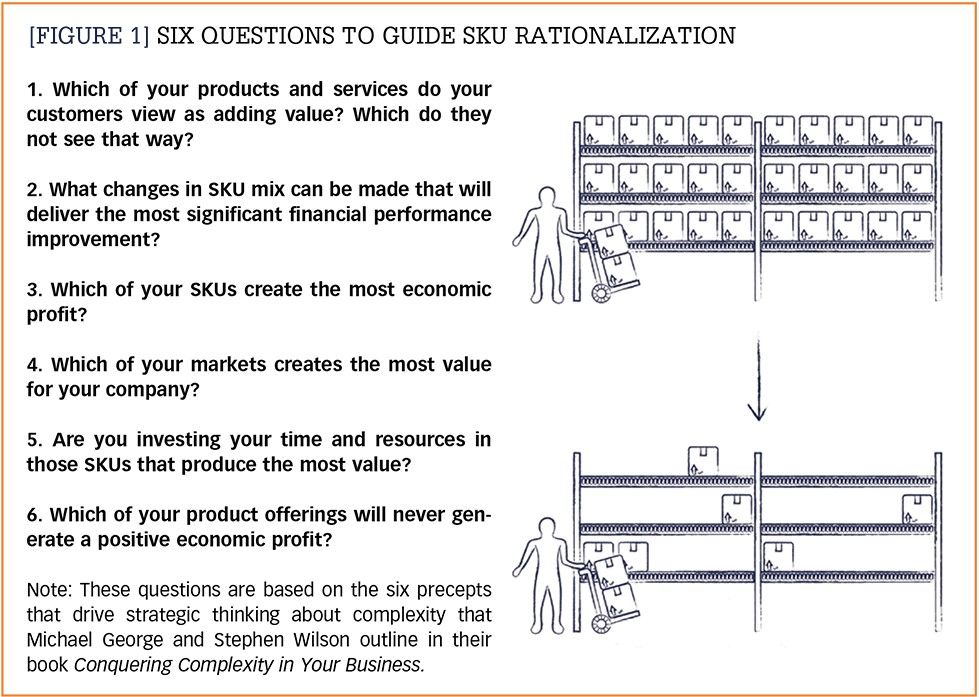

In doing so, we can apply the following six related precepts that are provided by George and Wilson (see Figure 1):7

1. Understand what is and is not value-add from the customer's perspective. What are the products and services that the customer views as value-add or as differentiators and as such are willing to pay for?

2. Realize that your biggest gains will come from step-change improvements. What SKU changes can be introduced that will deliver significant financial performance improvement?

3. Know that the majority of your value creation likely resides in 20% to 50% of your product and service offerings. Focus on what matters most and work to eliminate those offerings that detract from your performance.

4. Realize that value share and market share drive different behaviors and levels of profitability. In general, it makes sense to think in terms of value share (the percentage of total potential value creation in a given market or industry) instead of market share. Assess how the market is rewarding or punishing complexity. Where is the value created within your industry?

5. Recognize that growth is driven by the value-driven application of your finite resources. Time and management are not free. Ensure a clear understanding of why, when, and how finite resources will be deployed, and the anticipated return on the associated investment.

6. First eliminate product offerings that can never generate positive EP. If you cannot salvage a low EP offering, get rid of it, and then focus your efforts on improving the performance of the remaining offerings.

Achieving alignment

Two of the biggest barriers to complexity reduction in general, and SKU rationalization in particular, are functional silos and self-motivated interests, alluded to as tensions between Sales and Operations earlier. Succeeding in SKU rationalization (one of the most difficult complexity-reduction decisions) is only possible when companies go beyond simply removing these barriers to not tolerating them at all. In other words, we need to achieve alignment between Operations and Sales so that they see themselves in a collaborative, rather than an adversarial, relationship. This is accomplished by establishing clear, strategic goals such as profitability, order fill rates, customer satisfaction, and net promoter score at a higher level within the company. These goals should then be cascaded throughout the organization and supported by lower-level tactical SMART (specific, measurable, achievable, relevant, and timely) goals. Depending on the strategic goals that are established, PCE and EP are tools that can be used to support performance reporting.

Metrics-based performance management is critical to achieving the established outcomes. Some of the operational performance metrics that can be applied to help us gain an understanding of the impact of SKU reduction include excess and obsolescence inventory provisioning costs, labor productivity, unit throughput, supplier scorecard performance, order fulfillment rates, overhead absorption, logistics expenses, and supplier expediting premiums. Sales performance metrics that can be applied to help us gain an understanding of the impact of SKU reduction are sales forecast accuracy, customer satisfaction, market share, new customers, sales wins and losses, product margin, and customer order bookings.

It is important to establish meaningful metrics that are not opposing, but rather synergistic, and can be used to measure performance against common goals. When done properly at the executive level, this will create the alignment that is necessary to remove organizational barriers and self-interests. This works to create a "win-win" scenario that fosters an environment in which shared values can successfully be employed.

The culture in which we operate plays an important role in achieving the appropriate balance of SKU offerings, and the alignment between Operations and Sales. To this point, SKU complexity reduction is supported by employees that operate within a culture that:

- Believes that conquering complexity (in this case, SKU proliferation) is an imperative

- Is supported by ongoing executive engagement

- Dedicates the resource required to deliver success

- Focuses on more fact-based and less anecdotal decision making. Fact-based decision making will utilize an analytical methodology and toolset (such as PCE and EP).

- Aligns performance metrics, incentives, and policies

- Nurtures close customer relationships by using clear and opencommunications supported by accountability andcommitted action

- Targets high-value opportunities

Continuous improvement

More is better, but only up to a certain point. We recognize the need for SKU rationalization. But, we also recognize that SKU rationalization decisions are affected by a company's industry, the technologies it uses, its customer sets, and cultural settings. We understand that there is no "one-size-fits-all" solution that is available when it comes to SKU management. Instead, we have described evaluation techniques and employee behaviors that can help companies improve their internal processes and performance in ways that can deliver meaningful SKU rationalization results.

It is important to realize that there is no panacea for the management of SKUs. SKU rationalization should be viewed not in absolute terms but rather in terms of continuous improvement. Companies will continually need to engage in the process of identifying which of their SKUs are providing value to the organization and sifting out those that are not. To succeed at this, both Sales and Operations will need to accept and be guided by common objectives. While a healthy natural tension will always exist between Operations and Sales, these common objectives will help diminish the functional silos and self-motivated interests that are barriers to complexity reduction. Furthermore, SKU rationalization decisions should be based less on anecdotal input and more on performance metrics that are used to deliver the required cross-functional consensus.

Notes:

1. Raymond Cocozza, "How SKU Analysis Helps DCs Assess the Impact of SKU Proliferation on Their Operation," Conveyco website (June 19, 2018).

2. Martin Mocker and Jeanne Ross, "The Problem with Product Proliferation," Harvard Business Review(May/June 2017).

3. Chad Rubin, "Understanding SKU Growth: How Increasing Inventory Affects Costs & Management," Skubana website(June 8, 2016).

4. Fabian Bannasch and Florian Bouche, "Finding the True Cost of Portfolio Complexity," McKinsey & Company (September 2016).

5. Xiang Wan, Philip Evers, and Martin Dresner, "Too Much of a Good Thing: The Impact of Product Variety on Operations and Sales Performance," Journal of Operations Management, Volume 30, Number 4, p. 316-324 (May 2012).

6. Michael George and Stephen Wilson, Conquering Complexity in Your Business: How Wal-Mart, Toyota, and Other Top Companies Are Breaking Through the Ceiling, McGraw-Hill Education, Edition 1 (May 1, 2004).

7. Ibid.

ALAN has been helping to connect nonprofits with logistics resources since 2005. Here supplies are packed up for transport and distribution to Hurricane Maria survivors in 2017.Photo courtesy of ALAN

ALAN has been helping to connect nonprofits with logistics resources since 2005. Here supplies are packed up for transport and distribution to Hurricane Maria survivors in 2017.Photo courtesy of ALAN The nonprofit Unity in Disasters needed 30 pallets of food transported to Jackson, Miss., to help Hurricane Ida survivors in 2021. ALAN was on hand to coordinate a response.Photo courtesy of ALAN

The nonprofit Unity in Disasters needed 30 pallets of food transported to Jackson, Miss., to help Hurricane Ida survivors in 2021. ALAN was on hand to coordinate a response.Photo courtesy of ALAN